Quality Control in Manufacturing

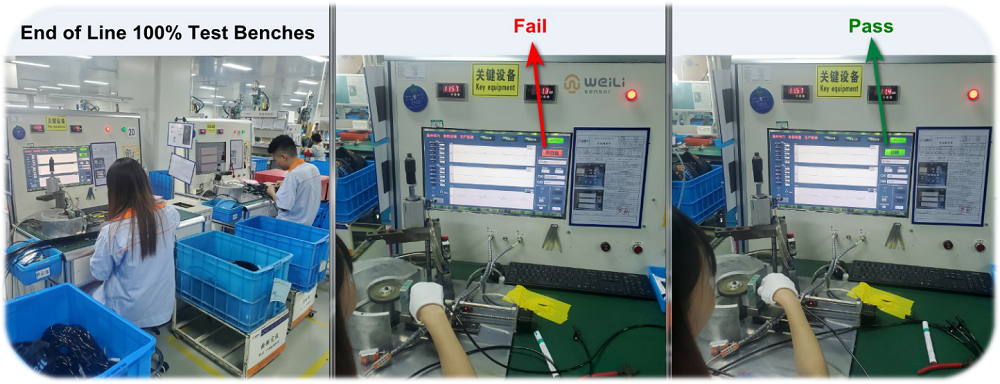

Weili has established and applies the IATF 16949: 2016 quality management system, complete quality control is implemented from the manufacturing process from components to final goods, all sensors are 100% tested before shipped to customers.

system judges automatically, no human judgment

| 1 Quality Standard

Working Instruction Standard Operating Procedure(SOP) Quality standard documents |

2 Materials

Incoming inspection Suppliers evaluation |

| 4 Finished Products

100% inspection Appearance Fitting Sizes Performances Accessories |

3 Production Process

Employee self-test First-end-inspection Process monitor and control 100% inspection for key process |

Quality Control Aftersales

Weili is concerned about the customer after sales experience very much, in any design and manufacturing process, there always are unpredictable problems that need resolving, expecially in automobile industry, we try to provide the best after sales supprt and once a complaint is happened, make the lost to the minimum.

| 1 Problem Description

Who, What, Where, When of the nonconformity, a specific description of the failure mode. |

| 2 Immediate Action in 24 Hours

Emergency actions , make the lost in the least. |

| 3 Root Cause analyses

To identify all causes and explain why the nonconformity occurred, and why the nonconformity was not identified. |

| 4 Corrective Action Plan

All possible corrective actions , to address the root cause of the problem. |